Client Name

A Leading Supermarket Chain in India

Industry

Retail & Logistics

Country

India

The client’s original sportsbook platform faced several key issues

Fleet Maintenance

Frequent vehicle breakdowns and reactive maintenance approaches severely disrupted the supply chain operations and delivery schedules. The lack of predictive maintenance systems led to escalating repair costs and significant logistics delays.

Route Efficiency

Manual route planning resulted in excessive fuel consumption and extended delivery times, particularly impacting perishable goods transportation. The absence of real-time optimization tools compromised delivery efficiency and operational costs.

Dock Management

Uncoordinated dock scheduling created severe congestion during peak hours at warehouse facilities. This bottleneck caused substantial delays in loading and unloading operations, affecting the entire supply chain performance.

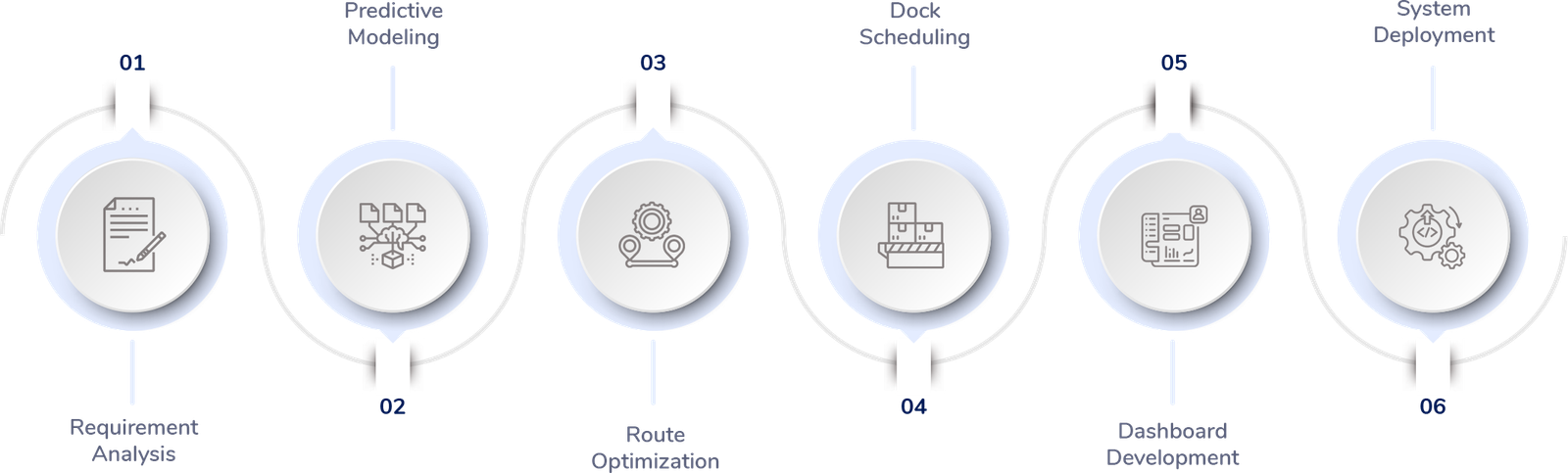

Our team implemented a unified, AI-powered logistics dashboard to address each of these pain points using advanced data analytics and machine learning techniques. The solution included

Predictive Maintenance Model

Using historical breakdown and servicing data, we developed a predictive maintenance model trained on various truck health metrics (e.g., engine temperature, fuel efficiency, mileage). This model leverages machine learning techniques to forecast potential breakdowns based on real-time data from sensors installed in the trucks.

AI-Driven Route Optimization

We used reinforcement learning to optimize routes based on real-time traffic, road conditions, and product requirements (e.g., cold storage for perishable goods). The system considers multiple constraints, including distance, travel time, fuel consumption, and the need for time-sensitive delivery.

Intelligent Dock Scheduling Model

We implemented a scheduling model based on queueing theory and priority-based algorithms that manages dock usage at warehouses. The model considers historical data on truck arrivals/departures, loading/unloading times, and dock availability to predict peak usage periods and allocate docks efficiently.

Unified Real-Time Dashboard

We developed a unified, intuitive dashboard that consolidates data from predictive maintenance, route optimization, and dock scheduling modules. The dashboard provides live tracking of fleet health, route status, and dock availability in a single view.

Our team achieved success which reflected growth, engagement, and satisfaction. Our team led to exceptional outcomes focusing on growing revenue and client base, elevating user satisfaction, and much more.

Reduction in Truck Breakdowns

Reduction in Overall Logistics Costs

Increase in Dock Utilization Efficiency

Improvement in Delivery Times for Perishable Goods

Improved Operational Control and Decision-Making

This case study demonstrates our ability to leverage AI and machine learning to solve complex logistics challenges in high-stakes, high-volume environments. By addressing critical pain points through predictive maintenance, route optimization, and dock scheduling, we delivered a robust, scalable logistics management platform that provides measurable value. This solution is highly applicable to industries such as retail, FMCG, and distribution, where fleet efficiency and real-time tracking are paramount to operational success

Learn how we worked with clients to overcome their challenges and created the best solutions and experiences in these case studies.